We at D Popatlal & Sons are committed to continuous improvement in all aspects of our operations and to achieving complete customer satisfaction through dedication, teamwork, and integrity. By understanding customer requirements, we focus on manufacturing safe, reliable, and cost-effective products with consistent quality.

We pledge to:

- Deliver high-quality products within the committed timeline.

- Foster teamwork to achieve common goals effectively.

- Continuously upgrade our products, processes, and resources.

- Provide dependable services that consistently meet industry standards.

Quality Objectives

- Ensure customer satisfaction by delivering high-quality products and services at competitive cost.

- Achieve on-time delivery for a minimum of 90% of orders, as per agreed terms and conditions.

- Conduct monthly training sessions for employees to enhance skills and knowledge.

- Limit internal rejections to 2% per batch or process.

- Reduce customer complaints and non-conformities in products, processes, and quality systems by at least 2% each year.

- Ensure 100% prompt response to customers and suppliers within 48 hours.

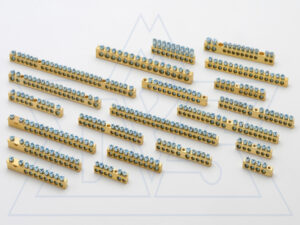

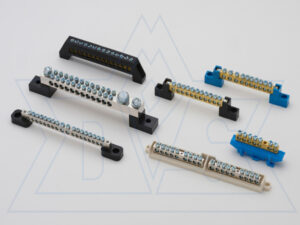

Quality Control

We follow stringent QC procedures to ensure every product meets customer specifications and dimensional accuracy. Our QC team performs systematic checks during and after production to guarantee defect-free outcomes.

Stages of Quality Control

Incoming Material Inspection

Composition, hardness & surface finish verified before production. Non-conforming materials rejected immediately.

In-Process Inspection

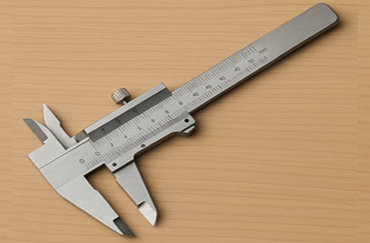

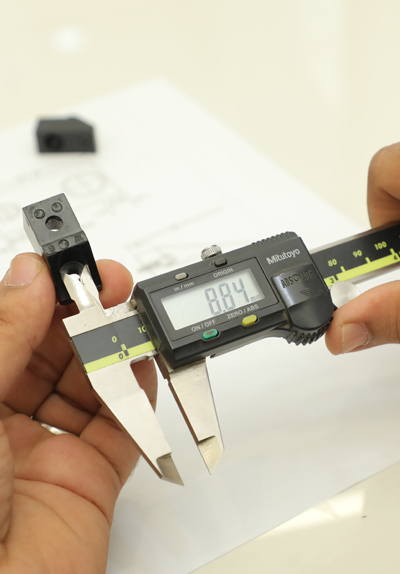

Stage-wise monitoring of machining & forming. Random sampling for tolerance verification with calibrated instruments.

Finished Goods Inspection

Dimensional checks of critical parameters, functional testing and packaging & labeling verification for safe delivery.

Specialized QC Testing

Hardness, tensile, conductivity & corrosion resistance tests plus NDT for spring steel & alloy parts.

Final QC Approval

Inspection reports & certifications prepared before dispatch. Only defect-free & fully compliant products are shipped.

Quality Assurance

At D Popatlal & Sons, quality is not just a process it is our commitment. Every product undergoes rigorous procedures to meet global standards of performance, durability, and reliability.

Raw Material Inspection

Ensuring material quality before production.

- Verified through Spectrometer / XRF for accurate chemical composition.

- Only certified and approved raw materials released for production.

Process Assurance

Controlled production & compliance checks.

- Standardized production procedures & work instructions.

- Regular audits for ISO compliance & customer requirements.

Final Product Validation

Thorough checks before dispatch.

- Batch-level validation: mechanical, chemical & surface quality checks.

- Specialized tests: plating thickness, corrosion resistance & impact performance.

Documentation & Traceability

Records & traceability across production.

- Detailed records maintained from raw material to finished goods.

- Full traceability & accountability for every product.

Continuous Improvement

Ongoing optimization & technology adoption.

- Periodic review of processes & testing protocols.

- Adoption of advanced technologies & feedback-driven improvements.